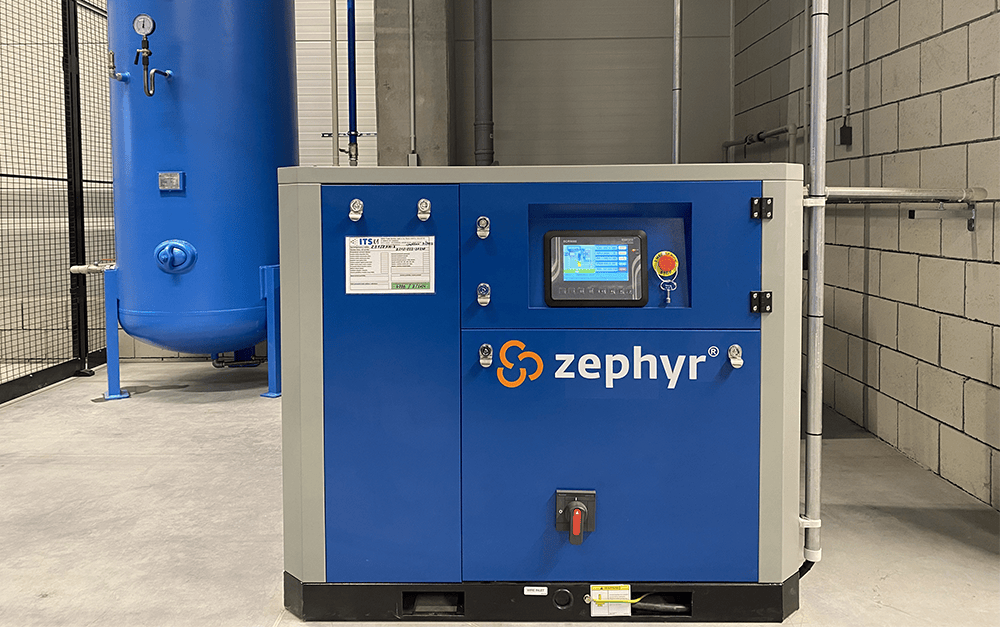

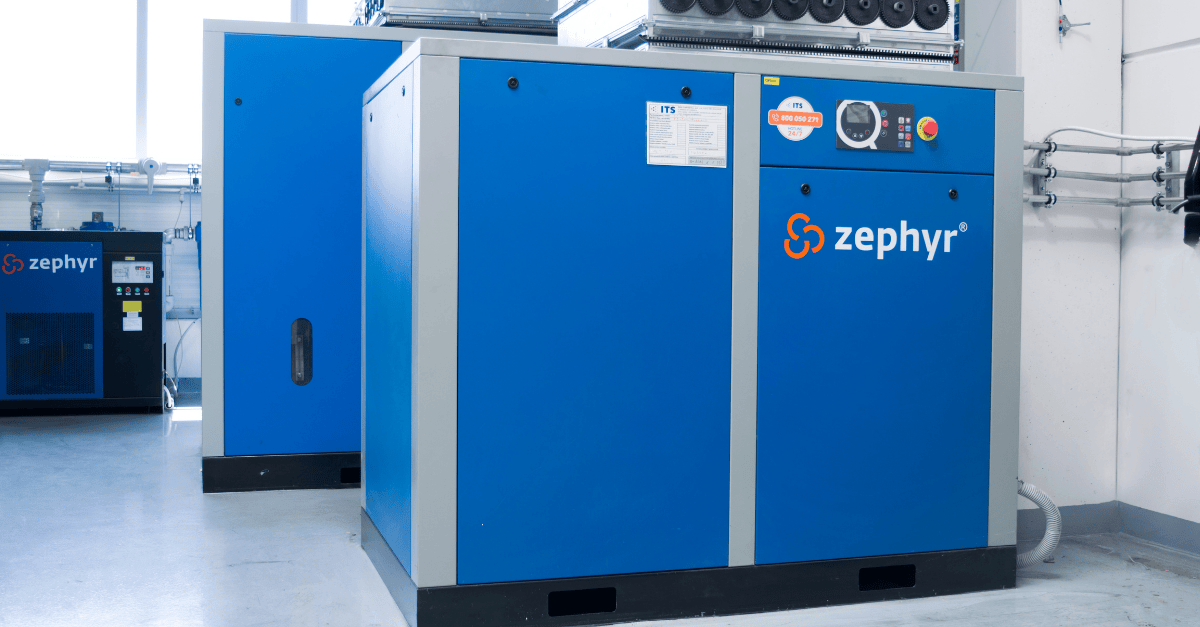

5 otázek, které byste si měli položit před výběrem kompresoru

Při výběru správného typu kompresoru a příslušenství je nezbytné mít co nejpodrobnější informace o typu vaší výroby a jejím vytížení z pohledu spotřeby stlačeného vzduchu. Představíme vám 5 základních údajů, které vám při volbě pomohou.