Do you know anyone who might be interested?

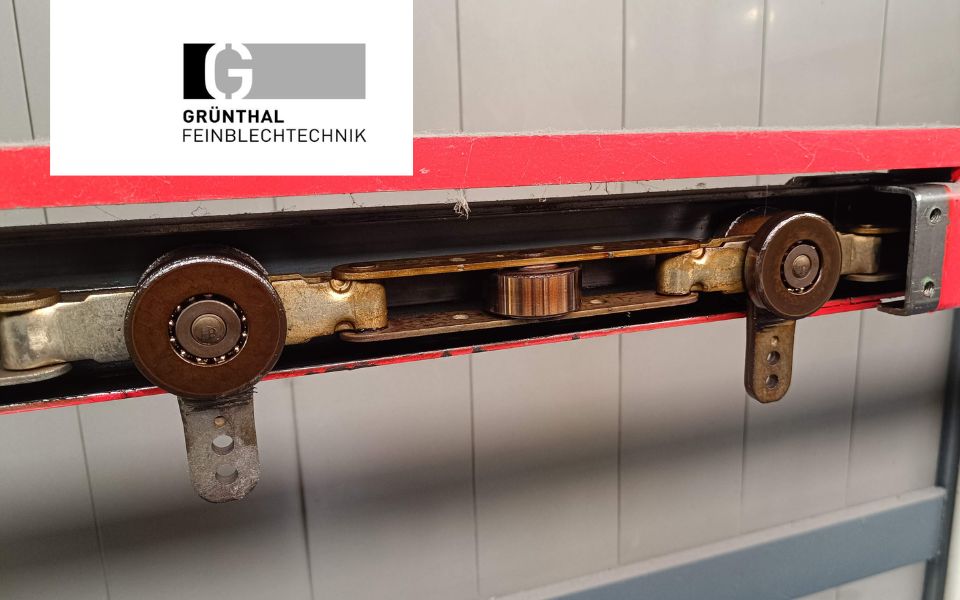

The leading spring manufacturer was no longer satisfied with the load capacity of the conveyor at the existing coating line and also needed to replace the existing Control system. Due to demand for perudiction and coating of larger springs, we increased the load capacity of the conveyor from 200 kg to 750 kg per one hanger.

| Customer | HŽP a.s. |

| Year of Realization | 2019 |

| Technology |

|

In addition, we had to keep the existing steel support construction, only reinforcement was allowed. Thanks to the new Power&Free conveyor, the customer has significantly increased capacity and also possibility to hang and coat a new types of products.

Simultaneously with the reconstruction and increasing the load capacity of the conveyor we implemented a new Control system HiVison® of the coating line. Requirement was to keep the connection with already existing Control system of application technology. Now the whole coating line including the application technology is conolidated under one Control system. Thi solution also increase s the capacity and efficiency of the coating line.

One of the chalanges of this project was a very short time to proceed a whole scope of work. We managed it with a two-day reserve and from the first day after hand-over of the project, the customer began to work in three-shift operation.

Show more information - Coating facilities

View productDo you know anyone who might be interested?