Coating facilities

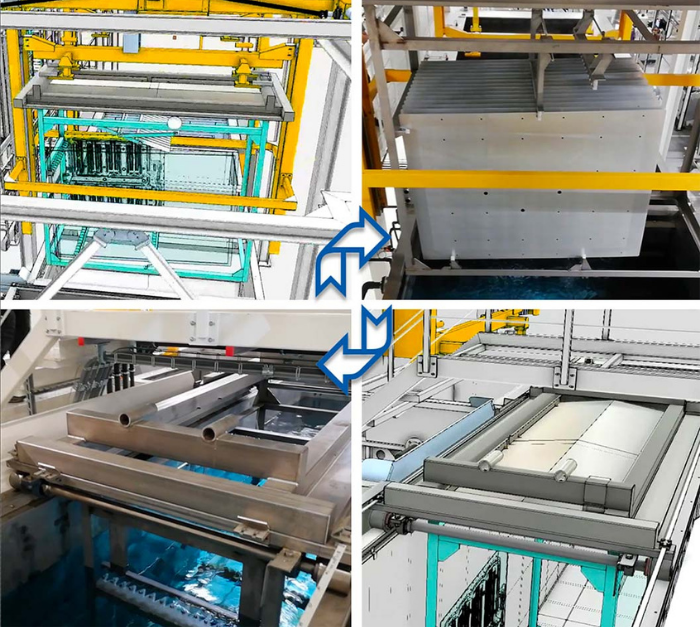

Virtual commissioning of technology

Virtual commissioning of technological processes before implementation brings many advantages. The aim of such a simulation is to verify all direct and related processes of the plant.

The operation of a larger technology, for example a paint line, consists of many different processes that are combined into a single unit. Such a simulation saves time spent on starting up the line and debugging the individual processes to a minimum.

In a virtual technology model, in which physical laws, technical standards, legislative limits or performance requirements are implemented, we fully simulate a complex operation. This allows us to identify and eliminate bottlenecks, risks or other circumstances that can negatively affect operations in advance.

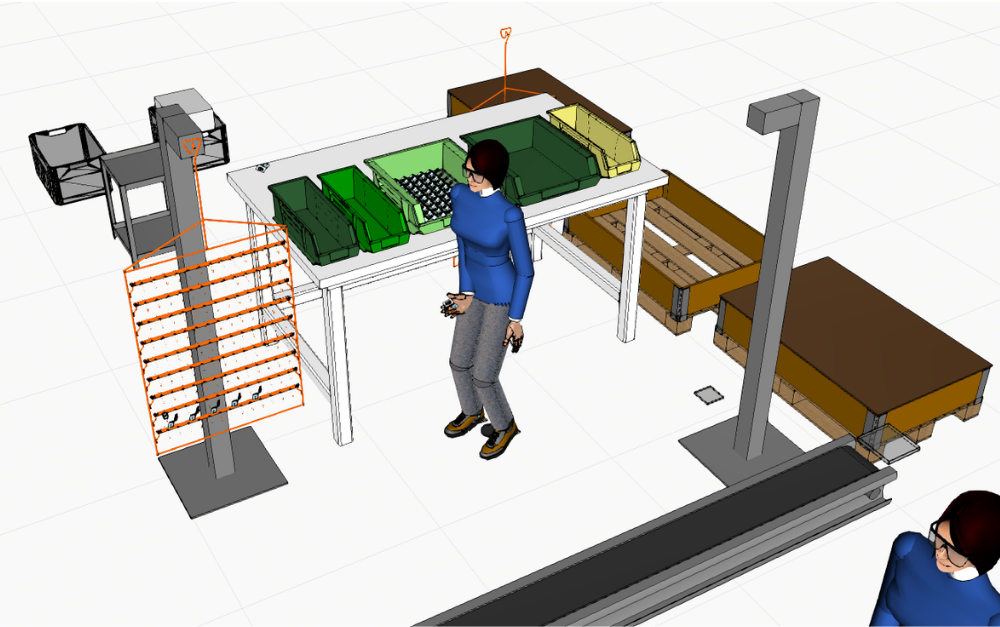

For example, we validate the complete logistics including associated parts, simulate the real pace and productivity of the technology, right down to determining the number of steps taken by workers when they are placed in the technology.

Of course, we present fully functional models in virtual reality, where the customer can see the entire technology 1:1 with his own eyes and get a perfect picture of it.

Read more in our article: Why use virtual commissioning technology

Are you interested in virtual commissioning technology?

Do you have a question or a specific request? Write to us.

Do you know anyone who might be interested?