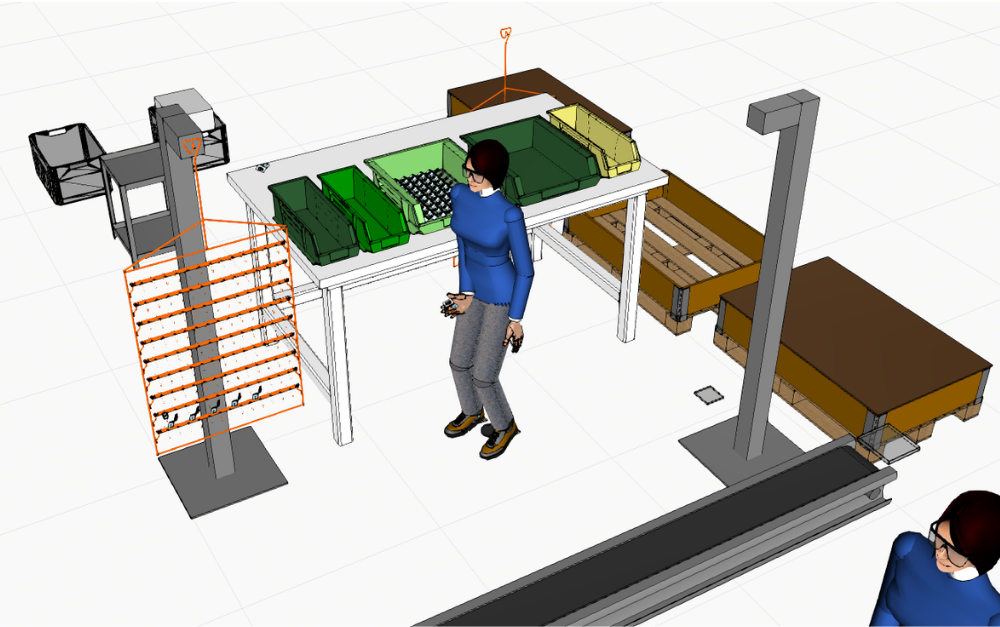

Školení pro hladký chod vaší lakovny

Aktuálně pro vás máme otevřená nejžádanější školení. Získejte odborné znalosti na našich školeních! Jsou vhodné především pro pracovníky z oblasti povrchových úprav, technology, kvalitáře, obsluhy linky, mistry nebo vedoucí lakoven.